Case Study / Healthcare Facility

Project Overview

This document provides insight into an energy audit project QEA Tech executed on a hospital complex. We were able to identify issues

causing preventable energy loss expenditure of $110,872 which was also causing 561 metric tons of Greenhouse Gases.

Problem Statement

The building management was facing increasingly high energy

expenditures and was finding it difficult to maintain appropriate

heating in certain areas of the building.

Objectives

The objectives of the project were to:

- Identify areas of energy loss in the building envelope

- Provide recommendations for targeted retrofits

- Provide an analysis of possible energy savings and estimated payback period

Building Details

Building Type: Hospital

Geographical Location: Ontario, Canada

Land Covered: 1.9 million sq. ft.

Construction: Constructed in late ’80s; the most recent

construction on the complex was done in late 2000s

Weather Conditions

- Warm and partly cloudy summers

- Mostly cloudy and freezing, snowy winters

- Annual temperatures vary between 16 and 79 degrees

- ASHRAE weather zone

Pre-Operation

The QEA operations and project teams conducted a pre-operation

plan after meeting the property manager. The plan consisted of

the following:

- Pre-ops questionnaire filled out by the property manager sharing details about the building envelope and equipment which is used later on in the analysis

- Flight plan created by the drone ops team to be used for the drone flight and thermography operation

- Operations scheduling done with the property manager to align on the data and time for the ops.

Operation

The operation preparation phase began at 9:20 p.m. on

December 3, 2020, for the complete aerial thermography

inspection of the building. The operation started at 9:30 p.m.

Aerial thermography inspection of the north and south parts of

the building concluded at 9:50 p.m., where all facade elements of

the building were thoroughly scanned by industrial UAV units

equipped with advanced thermal and visual imaging systems.

Through this operation, 90+ data points were captured from the

building, and the most concerning areas of interest are included

in this study. These data points were analyzed through QA Tech’s

analysis algorithms and validated by the QEA Tech technical team.

Different areas of interest on the building were analyzed further,

and Qualitative and Quantitative Thermography Reports were

generated for such building sections.

Post-Operation

The images captured during the operation were processed by the

QEA Tech team for a qualitative and quantitative analysis in QEA

Tech proprietary software. The Building Science team used the

information provided by the property manager alongside the

outputs generated by the software to create final reports for the

client.

Key Issues

- Thermal bridging (energy loss due to uninsulated connections between building elements)

- Potential cracks (potential risk to structural integrity of the building)

- Underperforming IGU frames and door frames (energy loss due to uninsulated fenestrations)

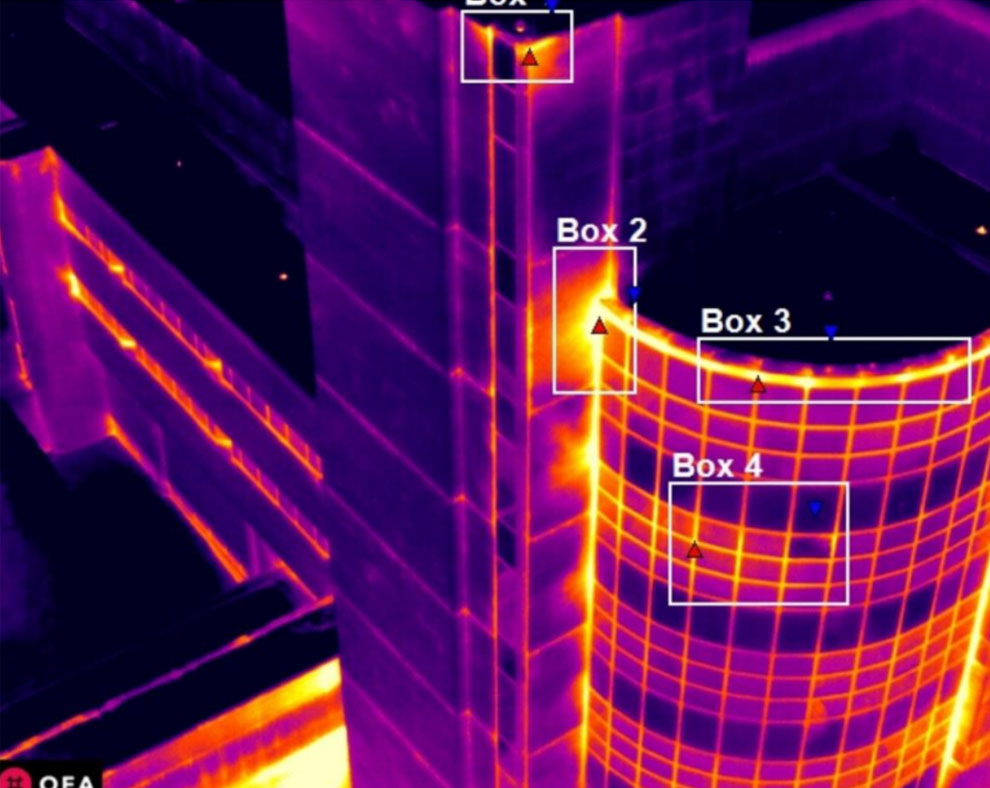

Thermal Imagery

This image shows a portion of the northern wall of the building

where the thermal behavior of various types of energy loss can be detected.

- Box 1 and Box 2: highlight massive thermal bridges along a vertical section of the building. Thermal bridges allow energy to escape from the building and potentially facilitate moisture leakage into the building.

- Box 3 and box 4: highlight heat loss from the parapet and window frames.

Key Findings

Average U-Value: 3.18

Building Code Value: 1.00. The building’s actual Uvalue is 218

percent over the building code.

The building envelope for this property is responsible for an

estimated 1817 MWh per year, while the Megawatts calculation,

which would yield the preventable portion of this energy loss, is

792 MWh per year.

Preventable Energy Loss

Assuming an equivalent kW cost ($eked) of $0.14/kWh would

translate to a total energy loss expenditure of $254,428, while

$110,872 of this amount is preventable. The preventable

energy loss would amount to 561 metric tons of Greenhouse

Gases.

Recommendations

- Replacement of failing windows and doors

- Additional sealant of framing of glazing elements

- Re-cladding to create a working path for water diversion

- Additional layer of insulation where applicable