Case Study / Multi-Unit Residential Building (MURB)

Project Overview

This document provides insight into an energy audit project QEA Tech executed on a MURB complex. The audit identified preventable energy loss expenditures exceeding $100,000, and exterior defects which were responsible for Greenhouse Gas emissions amounting to 171 tC02e.

Problem Statement

The building management was facing high energy expenditures

and failing building envelope elements and was looking for a

targeted retrofit plan to reduce operational costs while

minimizing capital burden.

Objectives

The objectives of the project were to:

- Identify failing building elements, including windows, doors, etc.

- Identify areas of energy loss in the building envelope

- Provide recommendations for targeted retrofits

- Provide an analysis on possible energy savings and estimated payback period

Building Details

Building Type: Multi-Unit Residential Building

Geographical Location: Ontario, Canada

Land Covered: 313,000 sq. ft.

Construction: Constructed in the early ’80s, this building has

been modified and expanded over the years.

Weather Conditions

- Warm and partly cloudy summers

- Mostly cloudy and freezing, snowy winters

- Annual temperature varies between 16 and 79 degrees

Pre-Operation

The QEA operations and project team created a pre-operation

plan after meeting the property manager. The plan consisted of

the following:

- Pre-ops questionnaire filled out by the property manager sharing details about the building envelope and equipment

- Areas of interest requiring special attention as specified by building operations team

- Flight plan created by the drone ops team used for the drone flights and thermographic scans

- Operations scheduling done with the property manager to align on the date and time for the scans

Operation

QEA Tech team began the operational preparation phase at 9:50

p.m. on November 4, 2021, for the complete aerial thermography

inspection of the building. The operation began at 10:00 p.m.

Aerial thermography inspections took two nights; varying façade

elements of the building were thoroughly scanned by industrial

JAV units equipped with advanced thermal and visual imaging

systems. The 3-D scan was completed at noon on November 6.

Through this operation, 700+ data points were captured from the

building, and the most concerning areas of interest are included

in this study. These data points were analyzed through QEA Tech’s

proprietary analysis algorithms and validated by QEA Tech’s

application team.

Pre-specified areas of interest on the building were analyzed

further, and Qualitative and Quantitative Thermography Reports

were generated for such building sections.

Post-Operation

The images captured during the operation were processed by the

QEA Tech team for a qualitative and quantitative analysis using QEA Tech proprietary software. The Building Science team used the information provided by the property manager alongside the outputs generated by the software to create final reports for the client.

Key Issues

- Uninsulated and/or failing windows

- Moisture accumulation

- Underperforming IGU frames and door frames (energy loss due to uninsulated fenestrations)

- Thermal bridging (energy loss due to uninsulated connections between building elements)

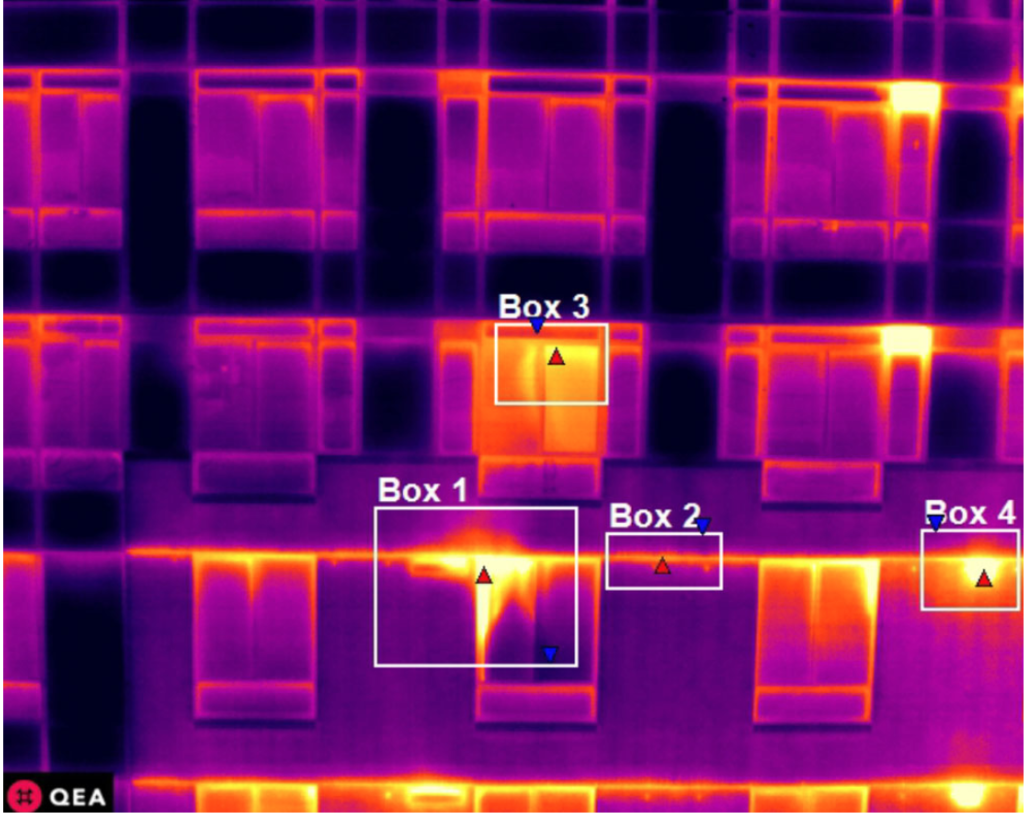

Thermal image

The image shows a portion of the eastern facade of the building

where the thermal behavior of various types of energy loss can be

detected.

- Box 1 shows signs of energy loss in the wall due to a failing connection between the wall and window frame.

- Box 2 displays signs of energy loss in the wall due to a poor or failed connection between the floor slab and exterior walls. Linear thermal bridge requires extra insulation and may require recladding.

- In Box 3, the insulated glass unit has partially or entirely lost its insulation gas, which causes energy loss through the window. IGUs typically contain argon gas between their layers. Argon gas can be replaced depending on how much the gas level has fallen and the extent of the damage.

- Box 4 displays signs of energy loss in the wall due to clogged exhausts.